Water jet loom

Water jet loom Air jet loom

Air jet loom Non-woven equipment

Non-woven equipment- > Fine opener

- > Carding machine

- > Cross lapper

- > Middle/High speed needle

- > Oven

- > Winder&cutter machine

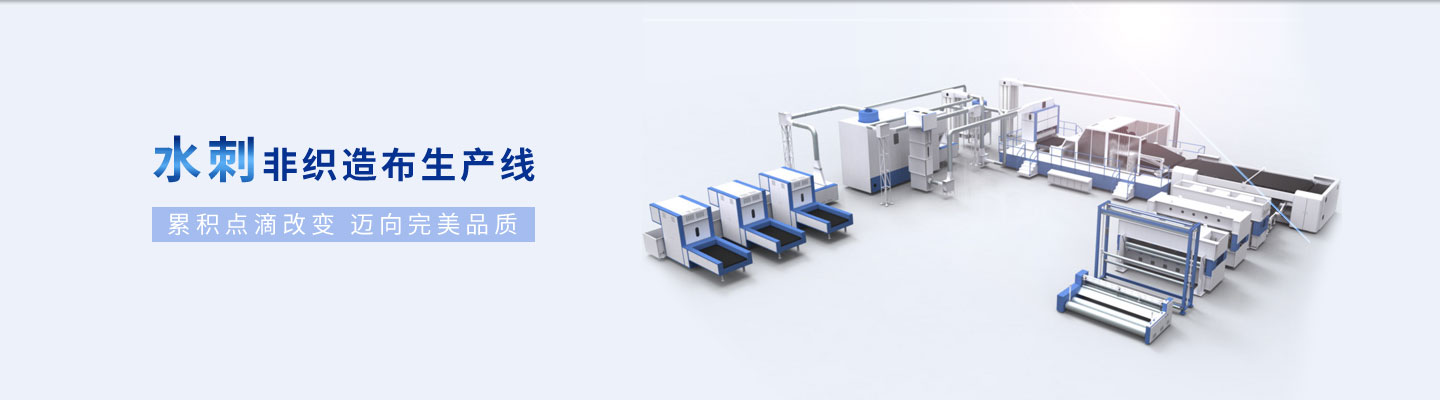

- > Spunlace

- > Production line of acupuncture

Rotor spinning machine

Rotor spinning machine- > Blowing carding machinery

- > Pressure cotton box

- > Carding machine

- > Draw frame

- > Rotor spinning machine

- > Roving machine

- > Ring spinning frame

- > Cone winder

- > Cone winder

Production Line

Production Line- > Bedding machinery

- > Pure cotton wadding

- > Polyester fiber wadding

- > Silk wadding

- > Comforter Production Line

- FA2203A carding machine

- Detailed introduction:

Second-ranking microcomputer control and industrial touch screen display relevant parameters. But flat flowers by copying itself replaced brush roller on knife chop. Second-ranking special jig, high strength, easy adjustment, facilitating large leak bottom removal The machine adopts the factory itself design production of new rack. Second-ranking avoided wallboard closed-end round wallboard flowers. Second-ranking brand-new appearance design, the beauty is generous. Second-ranking cotton lap or cotton box to double feeding. 40 seconds cylinder brake itself. (the user chooses) organization The machine itself more and get some continuous suck. In Washington, and stop five test device. Hung back, enhance flat second-ranking, improve the cotton nets quality. Second-ranking tin remain fascinating questions, improve precision structure optimization design. Before and after the number of fixed flats and set second-ranking hung board. Second-ranking can observe the cotton net aprons guide cotton device.

Technical specifications Applicable The machine is suitable for fiber length 22 ~ 76 mm cotton, chemical fiber and its blending. output 80kg/h sliver count 3.5~6.5(kg/m) feed weight 400~1000(kg/m) working width 1000mm total draft 60~300 licker-in diameter φ250mm licker-in speed 756 833 942 1025r/min

771 800 872 949r/min647 712 805 877r/min

doffer diameter φ706mm doffer speed 8.9~89r/min cylinder diameter φ1288mm cylinder speed cotton man made dibers 344 379 429 467r/min

300 331 374 407r/minno.of revolving 32/86 flat speed interval

Spinning fiber82~338mm/n71~294mm/min Additional carding After the taker-in plate, plate, former fixed cover Adjusted cylinder diameters for height φ600,φ1000mm

1100,1200mmContinuous aspiration air3500m3/h Export static pressure (absolute value) >-920pa Compressed air 4~5kg/cm3 Air consumption 0.01m3/h Total installed power 8.84kw Main transmission motor 5.5kw Doffer transmission motor 2.2kw Cleaning roller motor 0.37kw Cleaning roller is flat flowers motor 0.37kw To cotton motor 0.4 kw Safety cover form The fully closed Area (long x width) 4468×2735mm(φ600coiler)

4670×2120mm(φ1000coiler)Machine net weight 5500kg - On a:A186G carding machine next:FA1171 chute feeder